STEERING

TRUCK SERVICE MANUAL

NOTE:

On late production series

steering gears install a new retaining pin

to proper depth and replace roll pin.

20.

Position a new 0ring seal on housing cover.

Install cover assembly. It may be necessary to

use a soft hammer to tap the cover in place.

21.

Install the bolts and torque to proper

specifications.

22.

The relief valve plungers with the jam nuts may

now be installed using new O-rings. Turn them

approximately six turns. Final adjustment of the

plungers is made when the steering gear is

installed on the vehicle.

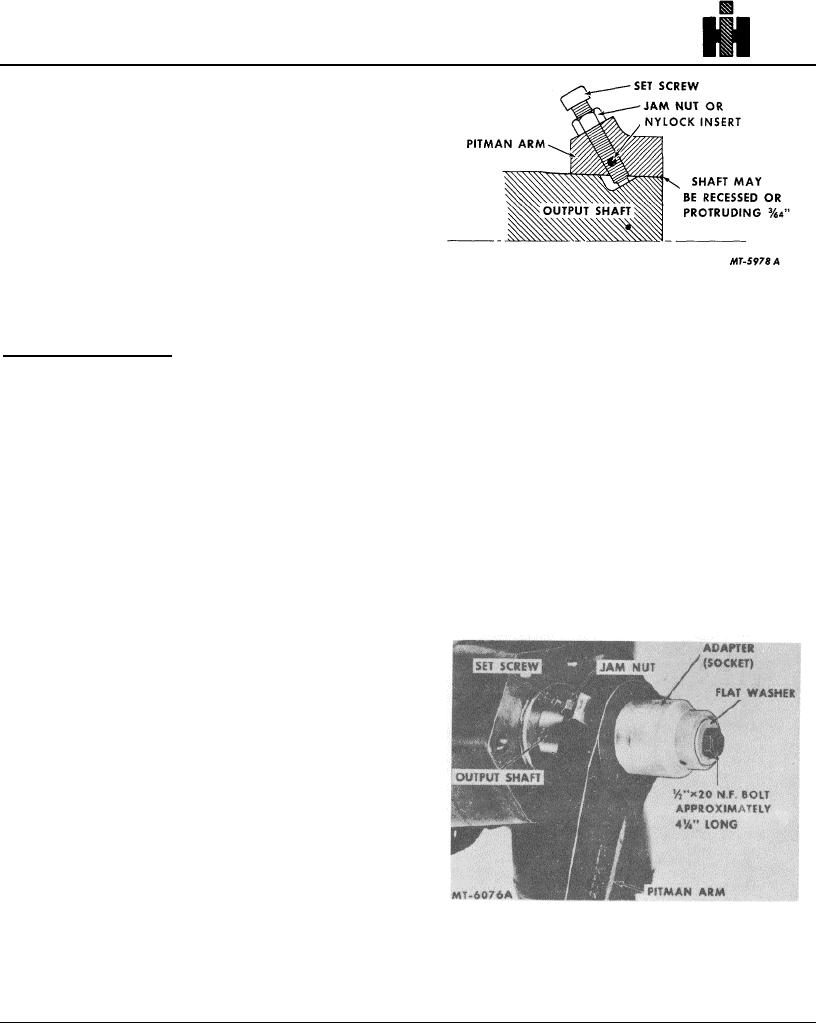

Fig . 35

With this method of retaining the pitman arm on the

FINAL ADJUSTMENTS

output shaft, two procedures are used when installing the

arm.

Bleeding Air from System

If the output shaft is equipped with a 1/2" x 20ONF or

After reinstalling the steering gear on the vehicle

9/16" x 18NF hole, a bolt approximately 4-1/4" long, an

but prior to installing the pitman arm, bleed the air from

adapter (large socket) and flat washer can be assembled

steering system in the following manner:

as shown in Fig. 36. Tighten the bolt to force the pitman

1.

Fill pump reservoir with SAE-10W-30 engine oil.

arm on the shaft. After the 1/2" bolt is tightened to 85 ft.

It will be necessary to continue filling after

lbs. or 9/16" bolt is torqued to 125 ft. lbs., the two

starting the engine and during the bleeding

setscrews are tightened to 15 ft. lbs. and then the jam

operation until correct oil level is maintained.

nut tightened. The 1/2" bolt, adapter and washer are

2.

Set parking brake or block wheels. Start engine

then removed.

and allow it to operate at fast idle speed.

3.

With engine running turn steering wheel from left

If the end of the output shaft is not equipped with either a

to right and return, making three complete cycles

1/2" or 9/16" threaded hole, the pitman arm should be

to remove all air from the steering system.

forced on the output shaft with a hammer.

4.

Stop engine.

The setscrews are then tightened to 12 ft. lbs. If jam

PITMAN ARM INSTALLATION

nuts are used, tighten them now.

NOTE: To provide proper alignment of

the pitman arm to the output shaft, an

arrow is stamped on the arm and a dot

(or indentation) is on the output shaft

end. These marks must always be in

alignment when the pitman arm is

installed on the output shaft.

There are two methods of retaining the pitman

arm on the output shaft:

1.

Two setscrews are threaded into the pitman arm

and are tightened into a "V" type groove in the

output shaft. Setscrews are either equipped with

a Nylock insert or jam nut to secure setscrews in

Fig. 36

place, Fig. 35.

NOTE: In either case the shaft may be

recessed or protruding 3/64" maximum

from outer face of pitman arm.

645