TRUCK SERVICE MANUAL

STEERING

CLEANING, INSPECTION AND REPAIR

Cleanliness is of utmost importance. Use clean

solvent to wash grease, oil or dirt from all metal parts.

Clean machined parts individually to avoid damage due

to "bumping" togPther of parts. Use lint-free cloths

dipped in a clean solvent to clean all machined surfaces.

After all parts are cleaned, dry parts with compressed air.

A careful visual inspection of the steering gear

parts is very important. Inspect components for burrs or

nicks, especially on or near the rack (teeth) on the piston.

If a raised burr is found on the piston, it should

be removed with a fine hand stone. All 0rings, seals and

gaskets should be replaced Inspect the output shaft

bushings for wear.

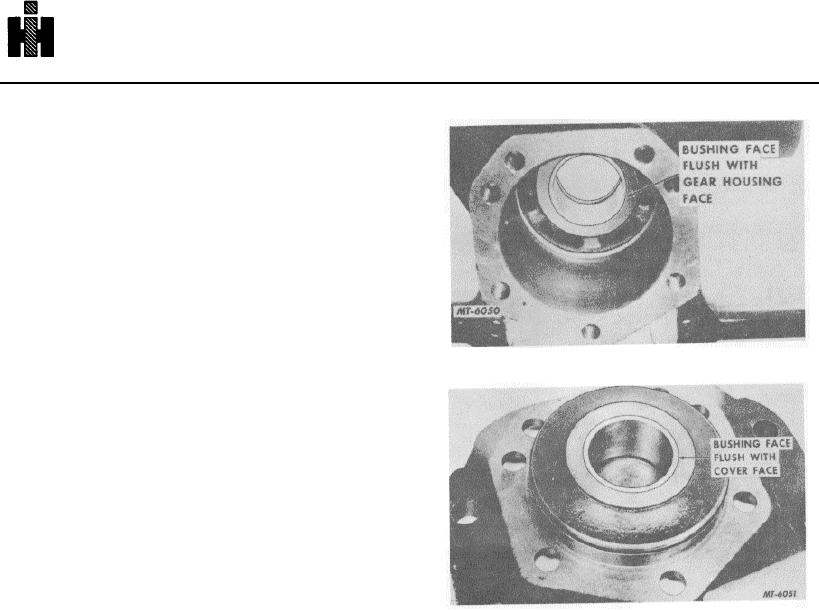

Fig. 28

REASSEMBLY

1. Install new bushings (if removed) in the gear

housing and cover, using a press and a straight

line pushing action. The bushing is pushed into

the gear housing, so that the inside face of

bushing is flush with inside face of gear housing,

Fig. 23.

When a new bushing is pressed into the cover,

the face of the bushing must be flush with the cover, Fig.

24. When reinstalling bushing in output shaft bore of

housing, if it goes in easily and heavy press resistance is

not encountered, carefully remove bushing. Thoroughly

Fig. 29

clean bushing of oil and grease and clean bore of foreign

material by scraping with a piece of brass sheet. Bushing

3. Position the relief valve spring and one relief

and bore should then be completely washed and dried.

valve ball into the valve bore. Then using a 3/16"

Coat exterior of bore and bushing with Loc-tite high

Allen wrench, install one of the valve seats. The

strength retainer compound. Reinstall bushing and allow

valve seats must be tight and flush with or

a minimum of six hours curing time. When the curing

slightly below the end surface of the piston.

time has elapsed, any excess Loc-tite in quad ring

groove or elsewhere should be -removed by washing

4. Install the second relief valve ball seat in the

with naphtha.

same manner.

2. Install a new quad ring in the groove in the gear

5. Position one of the reversing springs in bottom of

housing.

valve bore. Be sure spring is centered. The end

of the valve must enter the inside diameter of the

spring.

6. Install the valve positioning pin in the piston. Turn

pin inward with a screwdriver until it is below the

outside surface of the piston. The flats must

enter into the piston 1/4" to engage the mating

slot in the valve.

642