TRUCK SERVICE MANUAL

STEERING

13.

Press a new oil seal and dirt seal into bearing

cap, Figs. 31 and 32.

Lubricate surface between seals before

installing actuating shaft assembly.

(Use Ball Bearing Lubricant.)

14.

Press actuating shaft assembly into the bearing

cap, Fig. 33.

Fig .

33

15.

Install bearing retaining nut. Insert locking pin

through the hole in bearing cap and into the

hole in nut. If a new nut is being used, drill a

Fig .

34

3/32" hole in nut. The nut must be in place to

drill this hole. Drill through the locking pin hole

18

Insert output shaft in gear housing aligning mark

in the bearing cap and 3/16" into the nut.

on the center tooth on the pinion with mark on

the output shaft. NOTE: Be very careful so that

16.

Using a new gasket on the bearing cap thread

the gear tooth and rack tooth are properly

actuating shaft into the valve. Line up punch

aligned. If a tooth on the pinion strikes the

marks on gear housing and bearing cap. Turn

ground outside diameter' surface of the piston, a

shaft until cap comes into place on the end of

burr will be raised which will score the cylinder

cylinder. Check plunger hole alignment with

wall. This burr should be removed with a fine

valve seat in the piston. Tighten bolts to

hand stone before further assembly.

specified torque.

19.

Install the gear retaining nut. The nut must be

17.

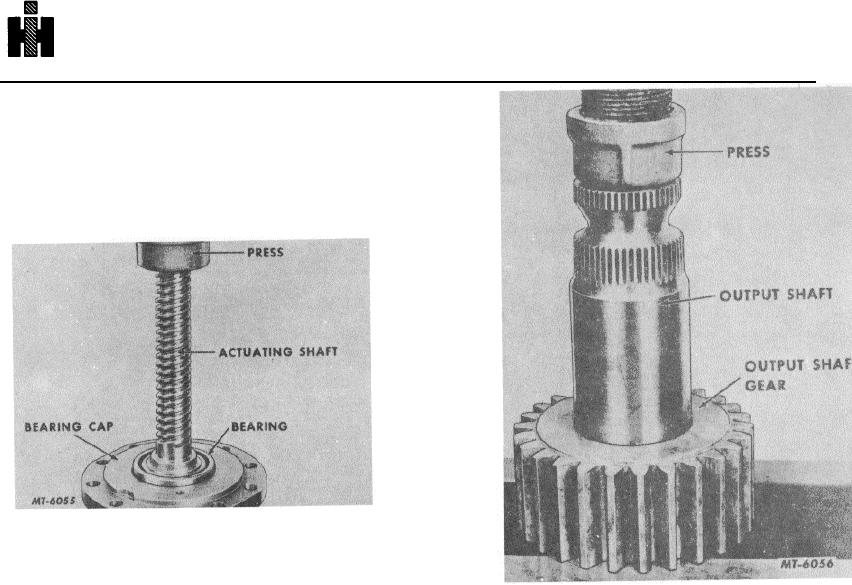

Align the timing mark on output shaft gear with

tight against the output shaft gear.

The

marked spline on the output shaft and

capscrews are then installed in the retaining nut.

reassemble. Use a press if necessary, Fig. 34.

If the holes do not line up with the gear, back the

nut off until they do. Tighten the capscrews with

an Allen wrench.

644