TRUCK SERVICE MANUAL

TRANSMISSION

INSPECTION AND REBUILD

Para 6-10

(8) Install support assembly 16 and snapring 19

into the valve bore.

(9) Place converter housing 16 (A, foldout 8) on

the work table, front side down.

(10) Place front support gasket 17 onto the

converter housing. Aline holes in the gasket with those

in the converter housing.

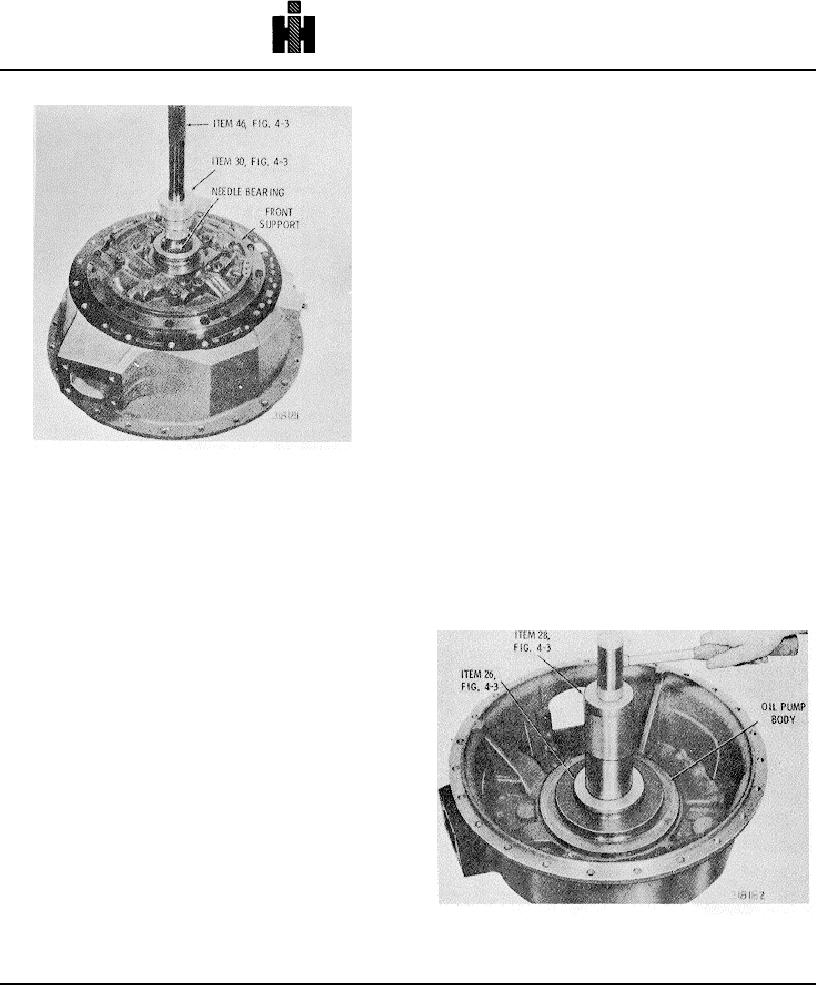

(11) Install front support assembly I (B, foldout 10)

onto converter housing 16 (B, foldout 8).

(12) Install three 3/8-16 x 2 1/2-inch bolts into the

front support (fig. 6-13). Tighten the bolts to 36 to 43

pound feet (49 to 58 Nm) torque.

(13) Install one 3/8-16 x 1 1/2-inch bolt into the hole

Fig. 6-17. Tool for installing front support needle

between the two valve bores that are closer to each

bearing.

other (fig. 6-13). Tighten it to 36 to 43 pound feet (49 to

58 Nm) torque.

(4) Install spring 4 and valve stop 5. Place washer

6 on spring 4 and compress the spring into the valve

bore until the snapring groove is clear (fig. 6-16). Install

(14) Install fifteen 3/8-16x 11/2-inch bolts into the

snapring 7.

outer bolt circle of the front support (fig. 6-13). Tighten

the bolts to 36 to 43 pound feet (49 to 58 Nm) torque.

(5) Install lockup shift valve 8, small end first, into

the bore indicated in B, foldout 10. Be sure the valve will

move freely of its own weight in its bore.

(6) Install spring 9 and valve stop 10. Place

washer 11 on spring 9 and compress the spring into the

valve bore until the snapring groove is clear (use spring

compressor). Install snapring 12.

(7) Install spring 13 into the converter regulator

valve bore indicated in B, foldout 10. Install converter

bypass valve 14 and valve seat 15. Spring compressor

is not required for this spring.

748