TRUCK SERVICE MANUAL

TRANSMISSION

INSPECTION AND REBUILD

Para 6-17

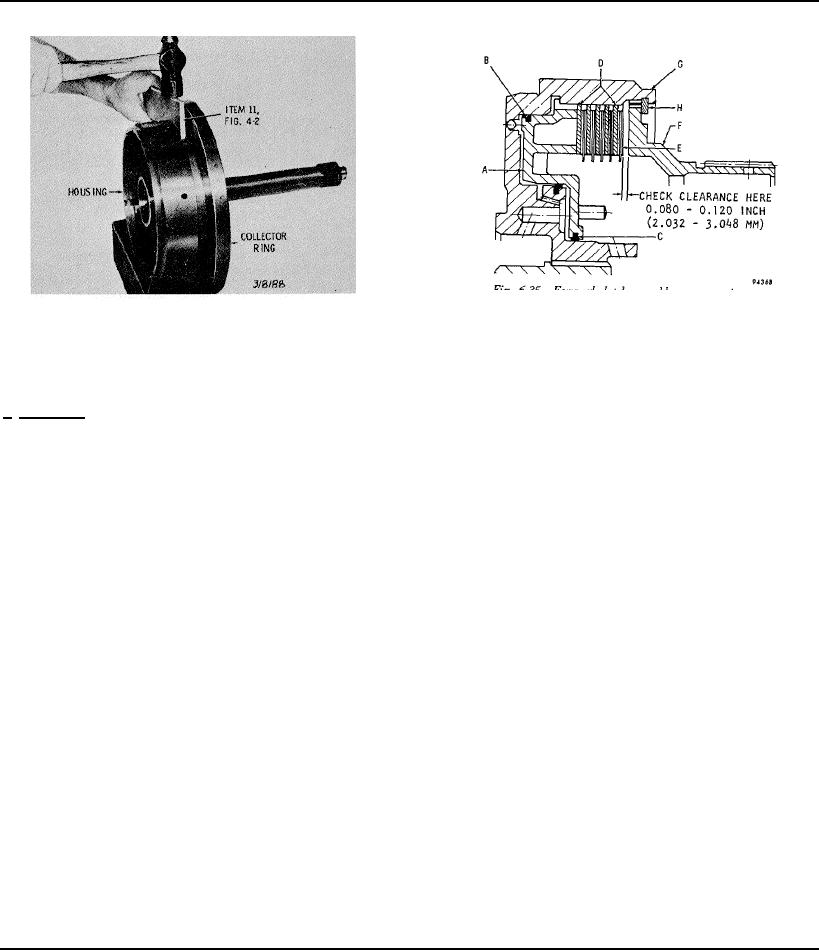

Fig. 6-34 Staking pivot collector ring to forward clutch

Fig. 6-35 Forward clutch assembly cross section

housing

(5) A clutch plate running clearance check is

NOTE

essential before completing the assembly rebuild. Items

Refer to paragraph 6-2, above.

(6) through (13), below, explain the procedure. Items (14)

through (20), below, complete the rebuild of the

b. Assembly (A, foldout 11)

subassembly.

NOTE

(1) If collector ring 6 was removed,

replace

If the forward clutch housing is replaced,

it with a new ring. Apply Loctite Retaining Compound 40

selection of a proper piston (A, B or C) is

to the joint and install the ring (fig. 6-33)Use installer 12

imperative before sealring installation. If

(fig. 4-2)to drive the collector ring onto the clutch housing

the forward clutch housing is not

(fig. 6-33)Use light hammer blows, and work around the

replaced and a new piston is required,

entire installer circumference.

make sure the identification letter

stamped on the new piston is identical to

(2) Using staking tool 11 (fig. 4-2), bend the

that on the old piston.

edge of the ring into the groove in the clutch housing (fig.

6-34)Check the four steel balls in the housing (fig. 6-

(6) Usingfigure6-35as a guide, place forward

32)They must be free to move, unobstructed, and

piston A on the work table with the return spring bosses

securely staked.

up. Grease and install lip-type sealring B and C, lips of

the seals facing downward.

(3) Position the forward clutch housing and shaft

assembly 5 (A, foldout 11), turbine shaft down, on a work

(7) Install piston A into forward clutch housing G.

table.

Make sure the lips of sealrings B and C are facing the

bottom of the piston cavity. Install seal protector 15 (fig.

(4) Grease and install sealring 12 into the

4-2) onto the clutch housing hub before installing the

sealring groove in the forward clutch housing. Be sure

piston (fig. 6-36).

the lip of the seal faces upward (rearward) (fig. 6-35).

(8) Beginning with an external-tangled plate,

CAUTION

alternately install five external-tangled plates D (fig. 6-35)

If sealring 12 is installed incorrectly, rough shifts in

and five internal-splined plates E into forward clutch

forward gears will occur.

housing G.

(9) Install fourth-clutch driving hub F into housing

G.

(10) Install snapring H.

752