TRUCK SERVICE MANUAL

TRANSMISSION

INSPECTION AND REBUILD

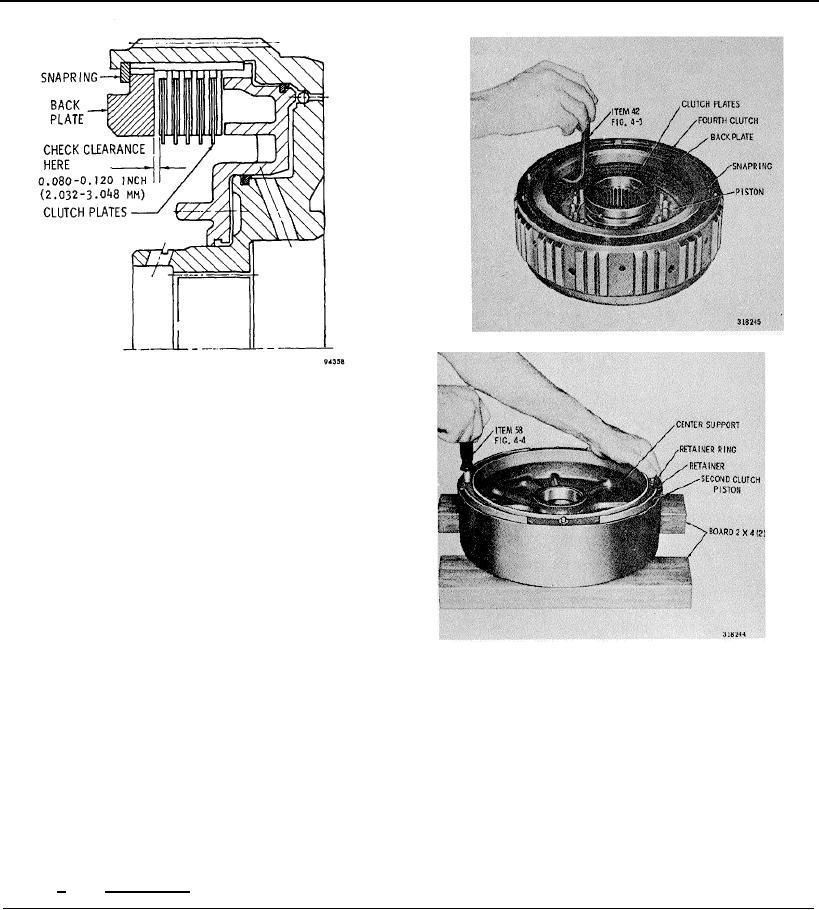

Fig. 6-4. Checking fourth clutch running clearance

Fig. 6-13 Fourth clutch assembly-cross-section view

step will not (fig. 6-44). The prescribed clearance is 0.

080 to 0.120 inch(2.03 to 3.05 mm). Any clearance

measurement within this range is satisfactory, but the

nearer to 0. 080 inch that can be attained, the longer the

clutch will maintain satisfactory clearance.

(8) Install 20 piston release springs, one each on

the 20 cast bosses on the fourth clutch piston (fig. 6-40).

(9) Install the spring retainer, recessed side

(outer lip) down, on the 20 piston return springs (fig. 6-

40).

(10) Compress the spring retainer until the

Fig. 6-45 Installing retainer rings onto second clutch

snapring groove on the clutch hub is clear (fig. 6-41).

piston

Install the snapring.

(1) Place center support housing assembly 16

(11) Grease (with oil-soluble grease) and install

(A, foldout 12), vertically (upright), on the work table.

the bearing race onto the rear hub of the fourth-clutch

housing (fig. 6-39).

(2) Remove pistons 10 and 21with attached

parts.

(12) Grease (with oil-soluble grease) and install

the bearing race onto the front hub of the fourth-clutch

(3) Remove the inner and outer sealrings from

housing assembly (fig. 6-38).

each piston. If replacement is necessary, disassemble

the

two

piston

assemblies.

Cut

the

6-19. CENTER SUPPORT ASSEMBLY

(A,

foldout

12)

a.

Disassembly

756