TRUCK SERVICE MANUAL

TRANSMISSION

HT 700D SERIES TRANSMI SSIONS

Para 6-19/6-20

foreign material. Install piston 21 into the rear of the

center support. Be sure the lips of both the inner and

retainer rings to prevent damaging the piston projections.

outer sealrings face the bottom of the piston cavity.

Remove four retainer rings, a retainer, and twenty

Leave the assembled third clutch piston (10) out of the

springs from each piston.

center support until final installation of the center support

assembly in Section 7.

(5) Remove two step-joint sealrings 13 (A,

foldout 12) from the hub of support housing 18.

(5) Lubricate needle roller bearing 14 and

bearing race 15 with oil-soluble grease. Install the race,

(6) Remove thrust bearing race 15 and needle

flat side first, onto the front hub of the center support. To

bearing 14.

facilitate assembly, keep the race square with the

support housing hub during installation. Forcing may

NOTE

damage the race. Install the needle roller bearing onto

the race.

Refer to paragraph 6-2, above.

(6) Carefully install two step-joint sealrings 13

b. Assembly (A, foldout 12)

into the sealring grooves of the support housing hub.

Retain them with oil-soluble grease.

(1) Temporarily place piston 10 in the front piston

cavity of center support housing 18. Install springs 9 into

the pockets of the piston. Aline spring retainer 8 on the

four ejector pin bosses of the piston. Compress the

springs by forcing the retainer into the recess at the outer

edge of the center support w hen the retainer rings are

installed (fig. 6-45). Install a new self-locking retainer ring

7 on the ejector pins of each piston, using installer 58

(fig. 4-4). Remove the piston from the center support.

(2) Repeat the procedures in (1), above, to

assemble items 21 through 24 (A, foldout 12) into the

rear cavity of support housing 18.

NOTE

If the pistons are not forced to the

bottom of their cavities during installation

of self-locking retainer rings 7 and 24,

proper clutch clearance cannot be

established.

(3) Grease (with oil-soluble grease) and install

inner sealrings 11 and 20, and outer sealrings 12 and 19

onto pistons 10 and 21. The lips of all sealrings must be

toward the piston cavities of the center support.

(4) Inspect the piston cavities in center support

housing

18

for

any

obstruction

or

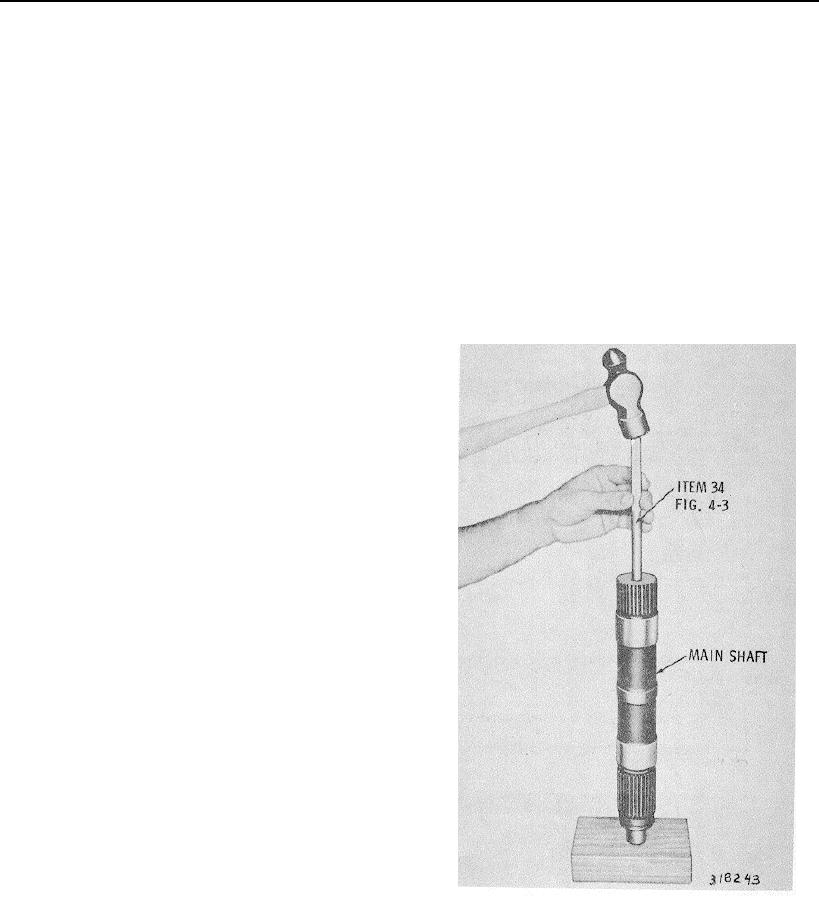

Fig. 6-17 Installing orifice plug into main shaft