TRUCK SERVICE MANUAL

TRANSMISSION

INSPECTION AND REBUILD

Para 6-24//6-25

the parts of the pinion group with the pinion pin holes in

the carrier.

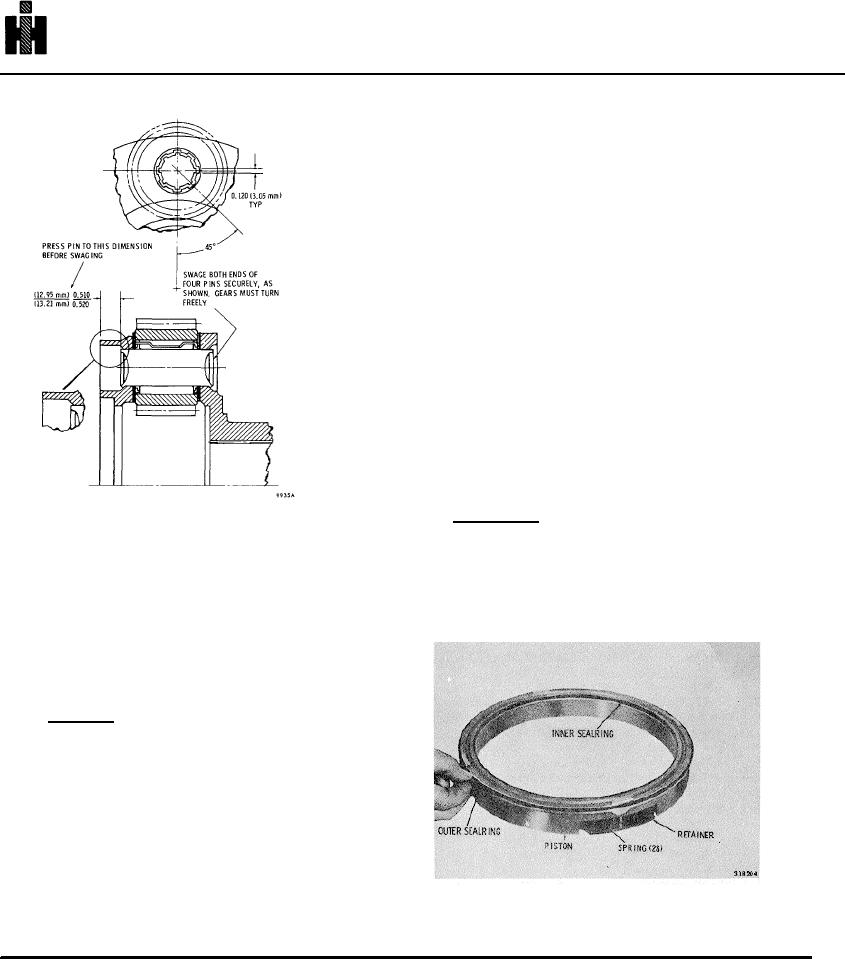

(3) Install pinion pin 20 and press it through the

carrier and pinion group to the dimension shown in figure

6-63.

NOTE

Pins must be a tight, to moderately tight, press

fit (when parts are at normal temperatures).

(4) Install the remaining pinion groups and pins in

the manner described above.

(5) Support each pinion pin on an 0. 812-inch (20.

62 mm) (approx) anvil. Using a suitable punch, swage

the pin firmly against the carrier to form the pattern

shown in figure 6-63. After swaging, each pinion must

rotate freely with 0. 008 to 0. 031 inch (0. 203 to 0. 787

mm) end play.

6-25. ADAPTER HOUSING ASSEMBLY

a. Disassembly (A, foldout 15)

Fig. 6-63. Components of low planetary carrier

assembly

(1) Position the assembly, piston assembly upward. Lift

out the piston assembly (includes items 3 through 8).

(3) Remove as a unit, each of the four pinion

groups consisting of pinions 23, thrust washers 21 and

(2) Remove the inner and outer sealrings from the piston

24, and needle roller bearings 22. Remove bearings

(Fig. 6-64).

from pinion bores.

NOTE

Refer to paragraph 6-2, above.

b. Assembly (A, foldout 15)

NOTE

To facilitate assembly, it is permissible to

freeze pinion pin 20 or heat carrier 19 before

pinion pin installation.

(1) Install bearings 22 into the bore of each pinion

23. Place a steel thrust washer 24 (first), and a bronze

washer 21 (last) onto each face of pinions 23.

Fig. 6-64. Removing (or installing) first clutch piston seal

(2) Position carrier 19 in a press, and place a pinion

ring

group (as assembled in (1), above) into the carrier. Aline

764