TRUCK SERVICE MANUAL

TRANSMISSION

Para 6-30

INSPECTION AND REBUILD

a. Disassembly ( A foldout 13)

(3) Place the carrier assembly in a press. Support

the carrier in such a manner that no stress will be placed

(1) Using a 5/8-inch drill, centered accurately, drill

on the swaged pins when the pinion pins are installed.

into one end of each pinion pin 12, until the swaged end

Place a pinion group (as assembled in (2), above) into

is sufficiently weakened.

the carrier.

(4) Carefully aline the parts of the pinion group

with the pinion pin holes in the carrier assembly, and

CAUTION

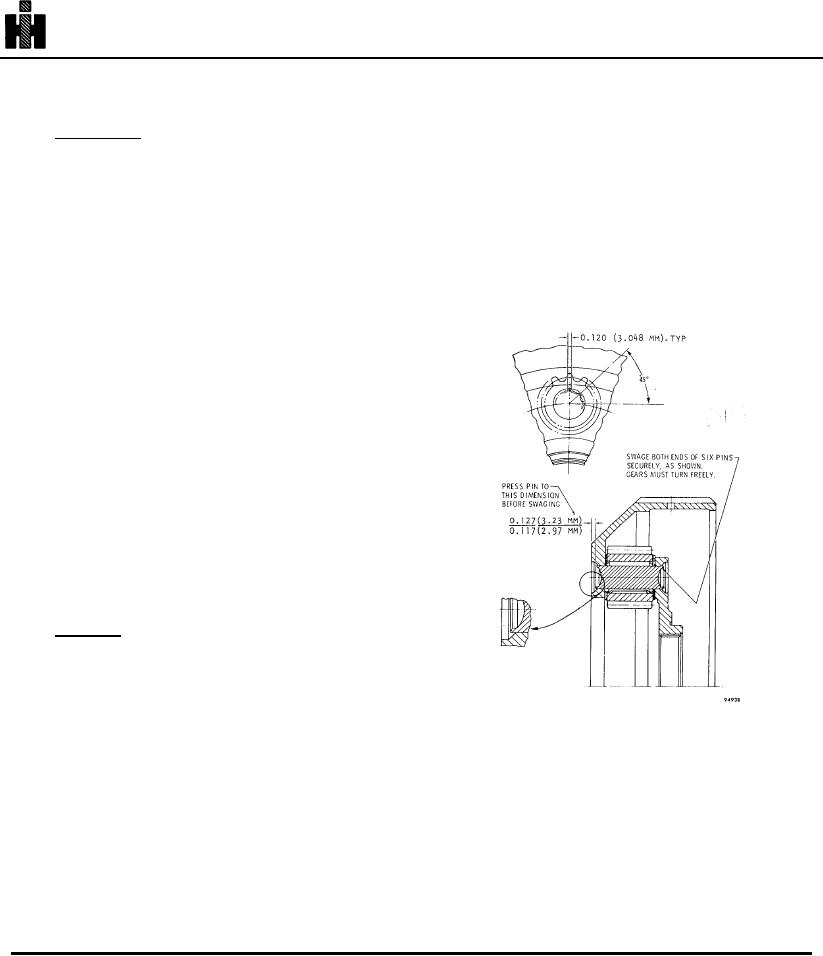

install pinion pin 12 (A foldout 13). Press the pinion pin

through the carrier and pinion group to the dimension

Do not drill into metal of carrier assembly 6.

shown in figure 6-68.

(2) Place carrier assembly 5 on a press bed.

Support the carrier in a manner such that no stress will

be placed on the swaged pins (smaller diameter) that do

not retain the pinions. Press six pinion pins 12 from

carrier assembly 5, shearing the drilled ends of pins 12.

(3) Remove as a unit, each of the six pinion groups

consisting of pinions 10, thrust washers 8 and 11, and

needle roller bearing 9. Remove the bearings from the

pinion bores.

(4) Inspect carrier assembly 6 for relative

movement bet w e e n the remaining parts. If looseness

is detected, replace the assembly.

NOTE

Refer to paragraph 6-2, above.

b. Assembly (A,foldoutl3)

NOTE

To facilitate assembly, it is permissible

to freeze pinion pin 12 or heat carrier 6

before pinion installation.

Fig. 6-68. Components of front planetary carrier

(2) Install a needle roller bearing 9 (A, foldout 13)

assembly

into the bore of each pinion 10. Place a steel thrust

washer 11(first) and a bronze thrust washer 8 (second)

onto each face of pinion 10.

768