TRUCK SERVICE MANUAL

TRANSMISSION

INSPECTION AND REBUILD

Para 6-32 -34

pin 46 until the swaged end is sufficiently weakened.

CAUTION

Do not drill into metal of carrier 40.

(3) Place carrier assembly 38 in a press, and

press four pins 46 from carrier 40, shearing the drilled

ends of pins 46.

(4) Remove, as a unit, each of the four pinion

groups consisting of pinions 43, thrust washers 42 and

45, and needle roller bearings 44.

NOTE

Refer to paragraph 6-2, above.

b. Assembly (A, foldout 13)

NOTE

To facilitate assembly, it is permissible

to freeze pinion pin 46 or heat carrier 40

before pinion pin installation.

(1) Install a needle roller bearing 44 into the

bore of each pinion 43. Place a steel thrust washer 45

(first) and a bronze thrust washer 42 (second) onto each

face of pinions 43.

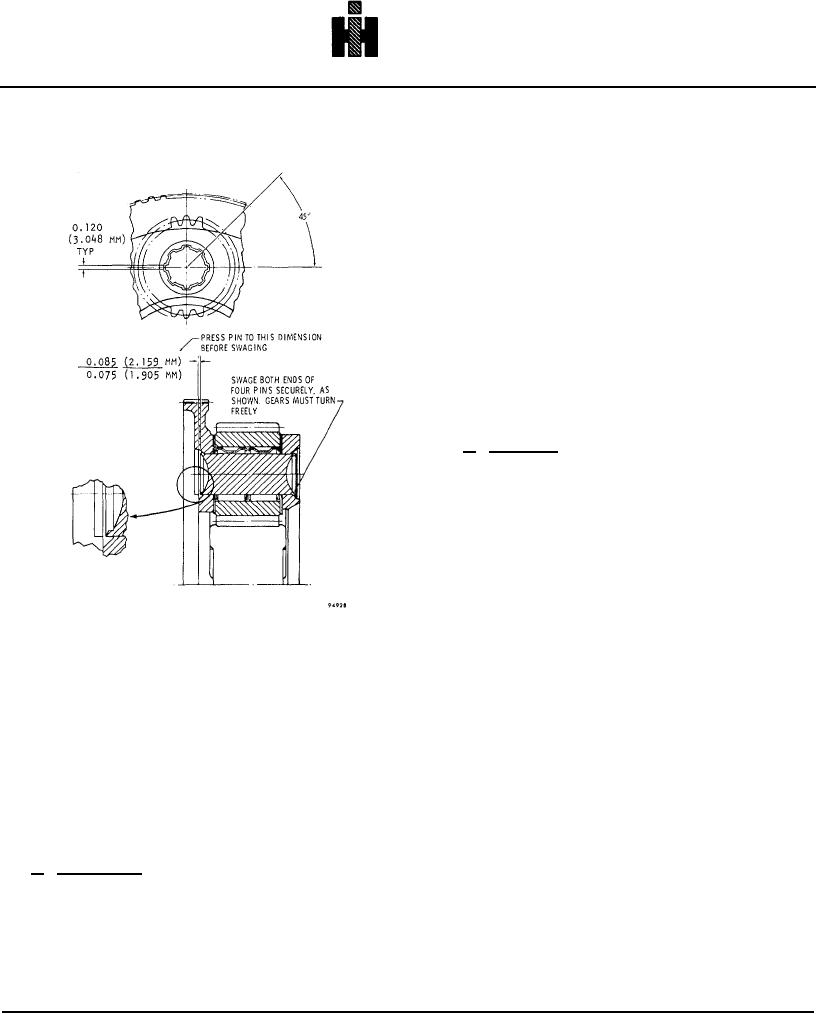

Fig. 6.69 Components of center planetary carrier

assembly

(2) Position carrier 40, front downward

(bushing bore upward), in a press. Place a pinion group

6-34. REAR PLANETARY CARRIER

(as assembled in (1), above) into the carrier. Align the

ASSEMBLY

pinion group with the pinion pin bore in the carrier.

NOTE

(3) Install a pinion pin 46, and press it through

Disassemble the planetary assembly

the carrier and pinion group, to the dimension shown in

only if there is evidence of undue wear

figure 6-72.

or damage.

Failure of one pinion

requires the replacement of the entire

NOTE

set, because the pinions are selectively

Pins must be a tight, to moderately tight,

matched.

press fit (when parts are at normal

temperatures).

a. Disassembly (A, foldout 13)

(1) If carrier 40 or bushing 41 is damaged or

otherwise unserviceable, replace with a carrier and

bushing assembly. Field replacement of the bushing

alone is not recommended.

(2) Using

a31/32-inch

drill,

centered

accurately, drill into one end of each pinion

770