TRUCK SERVICE MANUAL

TRANSMISSION

HT 700D SERIES TRANSM ISSION

Para 7-4

Fig. 7-9. Installing rear cover assembly

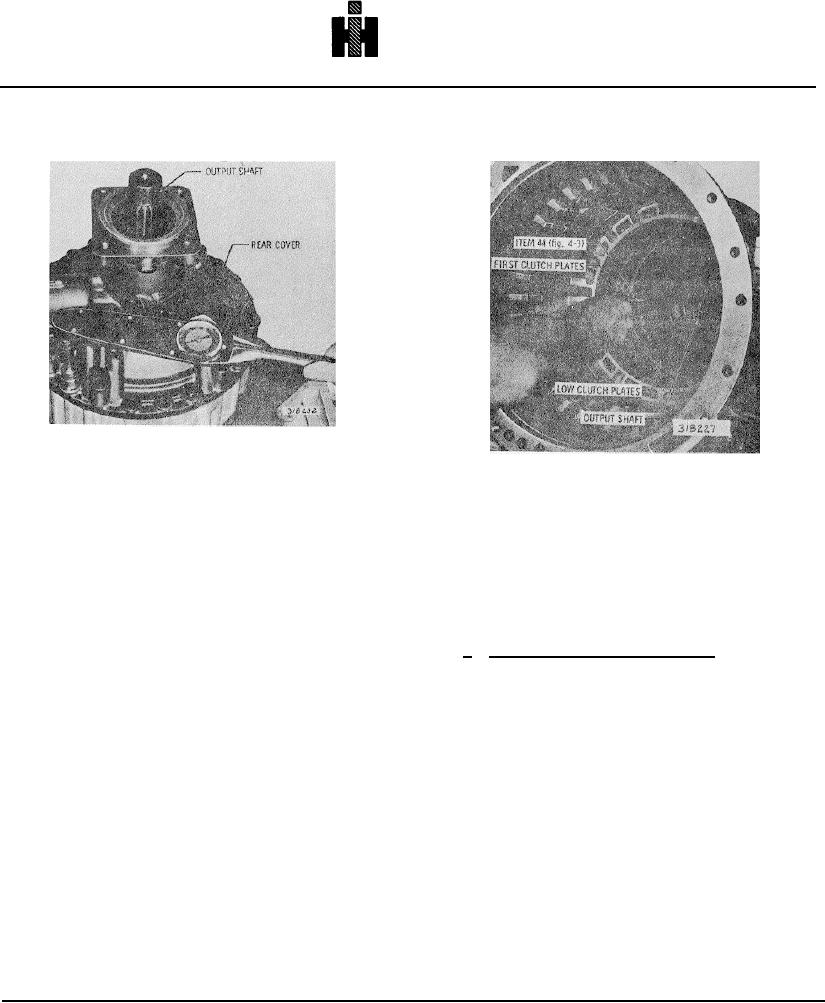

Fig. 7.10. Checking low clutch clearance

(4)

Beginning with an external-

tanged clutch plate, alternately install seven external-

to 3.68 mm). Any dimension within 0.095 to 0.145 inch

tanged and six internal-splined low clutch plates (refer to

(2. 41 to 3.68 mm) is satisfactory. However, the closer

Fig. 7-19).

the clearance is to 0.095 inch, the longer the interval

between clutch plate replacements will be. Clearance

(5) Install the rear cover assembly (as

must not be less than 0.095 inch. Replace worn clutch

assembled in para 6-22) and gasket onto the rear of the

plates with new plates to establish the desired clearance.

transmission housing and secure it with six 1/2-13 bolts

Recheck the clearance as described above.

and flatwashers, evenly spaced (Fig. 7-9). Tighten the

bolts to approximately 30 pound feet (41 Nm) torque.

b. Selecting Center Support Slapring

(6) Invert the transmission, front end upward.

(1) Install thirteen second clutch plate s,

Using gage 44 (Fig. 4-3), check the clearance between

beginning with an external-tanged plate. Alternately

the low clutch plates (fig. 7-10). It is recommended the

install seven external tanged plates and six internal-

gage be placed between the adapter housing wall and

splined plates (Fig. 7-3).

the first steelplate. The prescribed running clearance is

0.095 to 0.145 inch (2. 41 to 3.68 mm) Any dimension

(2) Install the clutch plate retaining snapring

within 0.095 to 0.145 inch (2.41 to 3.68 mm) is

(Fig. 7-4). Be sure the snapring gap is at the top of the

satisfactory. However, the closer the clearance is to

transmission housing.

0.095 inch, the longer the interval between clutch plate

replacements will be. Clearance must not be less than

(3) Remove the third-clutch piston from the

0.095 inch. Replace worn clutch plates with new plates

center support assembly (if not previously removed).

to establish the desired clearance.

Recheck the

Install bracket 5 (Fig. 4-2) into the recess between the

clearance as described above.

step-joint sealrings on the center, support hub (Fig. 7-5).

(7) Using gage 44 (Fig. 4-3), check the

(4) Install the center support into the

clearance between the first clutch plates (Fig. 7-11). It is

transmission housing (Fig. 7-5). Be sure the

recommended the gage be placed between the

transmission housing and the first steel plate. The

prescribed running clearance is 0.095 to 0.145 inch (2.41

775