TRUCK SERVICE MANUAL

TRANSMISSION

Para 7-1/7-3

Section 7. ASSEMBLY OF TRANSMISSION

FROM SUBASSEMBLIES

7-1. SCOPE OF SECTION 7

from the thicknesses of corresponding plates in later

models. Wear limits started in Section 8 are for plates

This section covers the assembly of the

presently supplied.

transmission. It is arranged in a continuous sequence to

facilitate assembly. Certain illustrations will not always

(3) If it is necessary to replace an external-

illustrate the model being assembled, but, when the

tanged plate, be sure the plate thickness is identical to

operation is identical, the illustration may be referenced

the original equipment. Refer to b(l) and (2), above.

and will correctly illustrate the procedure.

Keep the clutch plates separated; do not mix the plates

of one clutch with the plates of another.

7-2. CLUTCH CLEARANCES

(4) Clearance for the third clutch is

a. Preparation Procedure.

Preparations are

established during assembly. Clearances for the forward

required to establish the proper running clearance for

and fourth clutches are established during rebuild of

each clutch pack. Follow the procedures in b, below.

those subassemblies in Section 60

b. Determine Plate Thickness

(1) Determine the original thickness of each

external-tanged plate with a micrometer. Because the

tangs of the clutch plate are not subject to face wear, the

micrometer reading at a tang will be the original

thickness. Note that each clutch pack must contain one

thick plate next to the piston, and a basic number of thick

and thin plates. The combination of thick and thin plates

are selected to meet the prescribed clearance with the

clutch released. Install all thick plates toward the piston

end of the pack.

(2) Determine the wear on both internal and

external plates (refer to wear limits in Section 8).

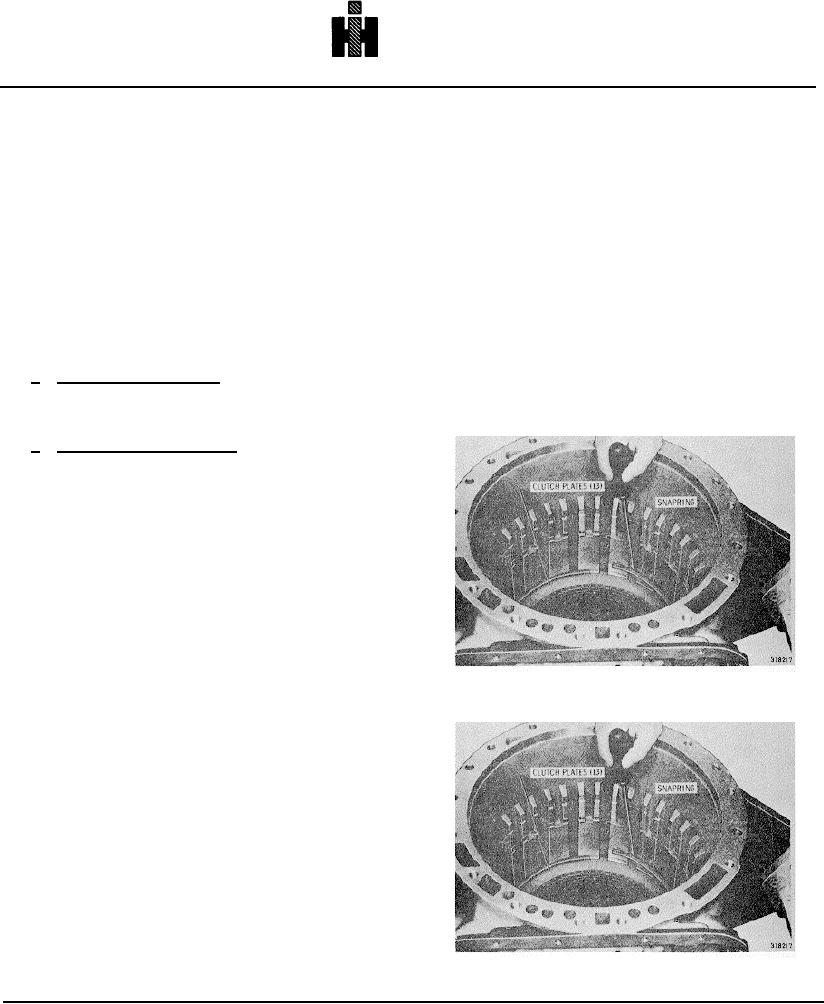

Fig. 7-3. Installing second clutch, external-tangled plate

Replace worn plates. Note that the thicknesses of

external-tanged plates in the low, first, second, and third

clutches in earlier models may be different

Fig. 7-4. Installing second clutch snapring

773