TM 5-3805-264-14&P

5-7.

HYDRUALIC CYLINDER REPAIR (Con’t).

tions.

Clean and inspect components in accordance with Chapter 4, Section III, General Maintenance Instruc-

Use extreme caution when handling heavy parts. Keep clear of heavy parts sup-

ported only by lifting device. Failure to follow this warning may cause injury to

personnel or damage to equipment.

Hydraulic cylinder sleeves may extend downward as hydraulic cylinder is lifted.

Expect sleeve movement any time hydraulic cylinder is handled. Failure to do

so may result in serious injury to personnel.

NOTE

Apply a light coat of lubricating oil to surfaces of components as they are

assembled.

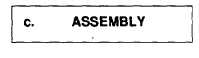

1.

Assemble hydraulic cylinder starting with the largest diameter sleeve and work-

ing inward.

If removed, install two bushings (35) to barrel (25) and bushing (34) to plunger (1).

NOTE

2.

Perform steps 2 thru 7 to install largest diameter sleeve.

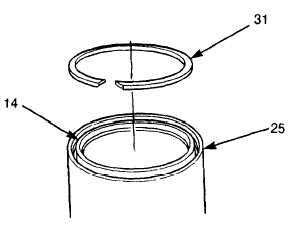

With hydraulic cylinder components in horizontal position, install two piston rings (33) and new wear ring

(32) to sleeve (14).

3.

Install sleeve (14) to barrel (25) and install bot-

tom retaining ring (31) to barrel using 5 in. seal

installation tool.

5-31