TRUCK SERVICE MANUAL

ENGINE

Table 14-9: Injector and Valve Set Position

Bar in

Pulley

Set Cylinder

Direction

Position

Injector

Valve

Start

A or 1-6VS

3

5

Adv. To

B or 2-5VS

6

3

Adv. To

C or 3-4VS

2

6

Adv. To

A or 1-6VS

4

2

Adv. To

B or 2-5VS

1

4

Adv. To

C or 3-4VS

5

1

Table 14-10: Engine Firing Order - Inline

Right Hand Rotation

Left Hand Rotation

1-5-3-6-2-4

14-2-6-3-5

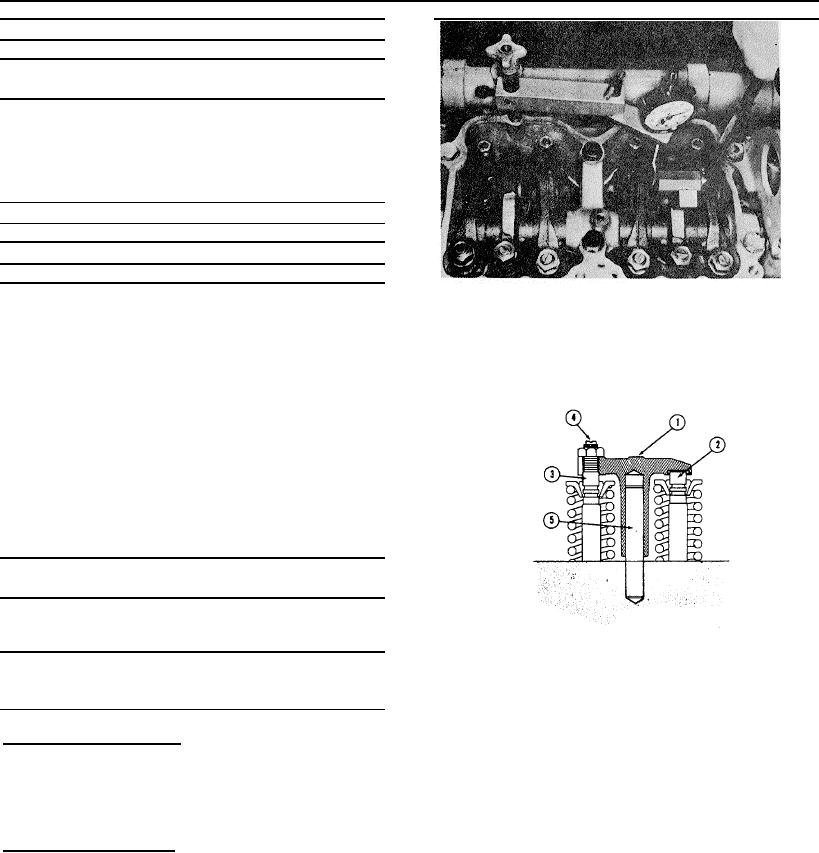

Fig. 14-28 (N114237), Bottoming Injector plunger in cup

5. Using ST-1193 Rocker Lever Actuator, Fig. 14-28, or

Crosshead Adjustment

equivalent, bar lever toward injector until plunger is

bottomed. Allow injector plunger to rise, bottom again,

set indicator at zero (0). Check extension contact with

1. Loosen valve crosshead adjusting screw locknut and

plunger top, turn adjusting screw until Adjustment Value,

back off adjusting screw, Fig. 14-29, one turn.

Table 14-11 is obtained.

6. Bottom plunger again, release lever; indicator must

show travel as indicated.

7. Tighten locknut to 30 to 40 ft-lb. [4.1 to 5.5 kg m] and

actuate injector plunger several times as a check of

adjustment. Tighten to 25 to 35 ft-lb. [3.5 to 4.8 kg m]

when using ST-669 Adapter.

Table 14-11: Uniform Plunger Travel Adjustment

Limits

Oil

Injector Plunger Travel

Valve Clearance

Temp.

Inch [mm]

Inch [mm]

1. Crosshead

4. Adjusting Screw

2. Valve Stem

5. Crosshead Guide

3. Valve Stem

Adj.

Recheck

Value

Limit

Intake

Fig. 14-29, (N21461). Valve croshead

Aluminum Rocker Housing

2. Use light finger pressure at rocker lever contact

surface(1) to hold in contact with valve stem (2). Turn

Cold

0.170

0.169 to 0.171 0.011

0.023

down adjusting screw until it touches valve stem (3).

[4.32]

[4.29 to 4.34] [0.28]

[0.58]

Hot

0.170

0.169 to 0.171 0.008

0.023

[4.32]

[4.29 to 4.34] (0.201

[0.58]

3. Advance setscrew an additional 20 to 30 deg. to

straighten stem on its guide. Using ST-669 Torque

Cast Iron Rocker Housing

Wrench Adapter, tighten locknuts to 22 to 26 ft-lb. [3 to

3.6 kg m] . If ST-669 is not available, hold screws with

Cold

0.175

0.174 to 0.176 0.011

0.023 [

screwdriver and tighten locknuts to 25 to 30 ft-lb. [3.5 to

4.45]

[4.42 to 4.471 (0.281

[0.58]

4.1 kg m].

Hot

0.175

0.174 to 0. 176 0.008

0.023

[4.45]

[4.42 to 4.47] 10.20]

[0.58]

4. Check clearance between crosshead and valve spring

retainer with wire gauge. There must be a minimum of

0.025 inch [0.64 mm] clearance.

408