TRUCK SERVICE MANUAL

ENGINE

Note: If generator or alternator pulley has been removed

or a new pulley is installed, use hardened steel washer

and locknut. Torque to values in Table 14-8.

Table 148: Torque Values (Pulley to Alternator or

Nominal Thread Size

Torque

Inch

Ft-Lb [Kg m]

1/2

50 to 60

[6.9 to 8.3]

5/8

55 to 65

[7.6 to 9.0]

3/4

90 to 100 [12.4 to 13.8]

Note: Exception to the above limits are:

1. Belt Deflection

Delco-Remy

Torque

2. Belt Free Span

Ft-Lb [Kg ml

1 0 DN 150

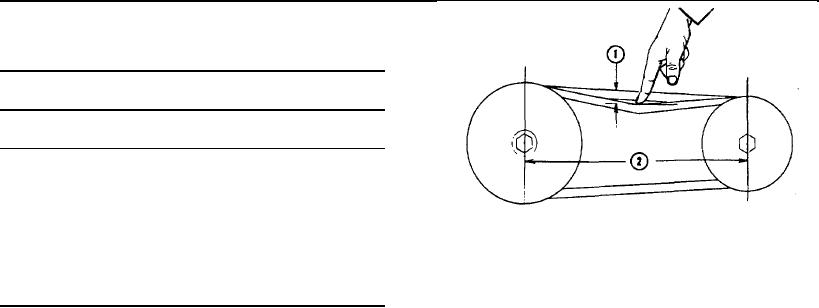

Fig. 14-24, (N11471). Checking belt tension manually

25 SI

70 to 80

[9.7 to 11.1]

Belt Tension

ADJUST INJECTORS, CROSSHEADS AND VALVES

1. Installation:

Before adjusting injectors and valves be sure to

2.

determine if rocker housings are cast iron or aluminum

a. When two or more identical belts are used on the

and use appropriate setting.

same drive, they must be replaced as a matched set.

Two methods of adjusting injectors and valves are

b. Shorten distance between pulley centers and install

described in this manual. The preferred method is

belt(s). Do not roll or pry belt over pulley.

Uniform Plunger Travel. This method involves adjusting

plunger with ST-1270 Injector Indicator Kit (consists of

c. Pulley misalignment must not exceed 1/16 inch [1.59

ST-1170 Dial Indicator, ST-1 193 Actuator and ST-1251

mm] for each foot [304.8 mm] of distance between pulley

Actuator) to a specified travel. The second method

centers.

involves setting plunger adjusting screw to a specified

torque setting. It is essential that injectors and valves be

d. Belts should not bottom on pulley grooves, nor should

in correct adjustment at all times.

they protrude over 3/32 inch [2.38 mm] above top edge

of groove.

Injector "Plunger Free Travel," as described below, must

be checked before adjustments are made.

e. Belt riding depth should not vary over 1/16 inch [1.59

mm] on matched belt sets.

Check Plunger Free Travel

f. Do not allow belts to rub against any adjacent part.

In order to prevent excessive loading of injector actuating

train and possible failure, check as follows:

2. Adjusting:

1. Back injector adjusting screw out 1-1/2 turns from

a. Use ST-968 for 3/8 to 1/2 inch [9.53 to 12.70 mm]

normal operating position, tighten locknut.

width belts. Use ST-1138 for 11/16 to 7/8 inch [17.46 to

22.23 mm] width belts.

2. With ST-1170 Dial Indicator extension on injector

plunger top, bar engine and record total amount of each

b. When belts are installed, tighten until a reading of 90

plunger travel. This is called "Plunger Free Travel" and

to 110 lb. force is obtained. New belts will loosen after

MUST NOT exceed 0.206 inch [5.23 mm] on any one (1)

running for an hour or more and may require re-

cylinder of engine.

adjustment. Recheck belt tension and re-adjust to 90 to

110 lbs. if reading is less than 80 lbs.

3. On engines with plunger Free Travel exceeding 0.206

c. As an alternate method, tighten belts so pressure of

inch [5.23 mm] the Torque Method of adjustment must

index finger extended straight down, Fig. 14-24 will

be used unless component changes (rocker levers

depress belt to the value shown in Table 14-5. Force

and/or cam followers) are made which will allow 0.206

applied (1) will be approximately 13 lb. [5.9 kg] for each

inch [5.23 mm] limit of Free Travel to be obtained.

foot

[0.30

ml

of

free

span

(2).

406