TRUCK SERVICE MANUAL

FUEL SYSTEM

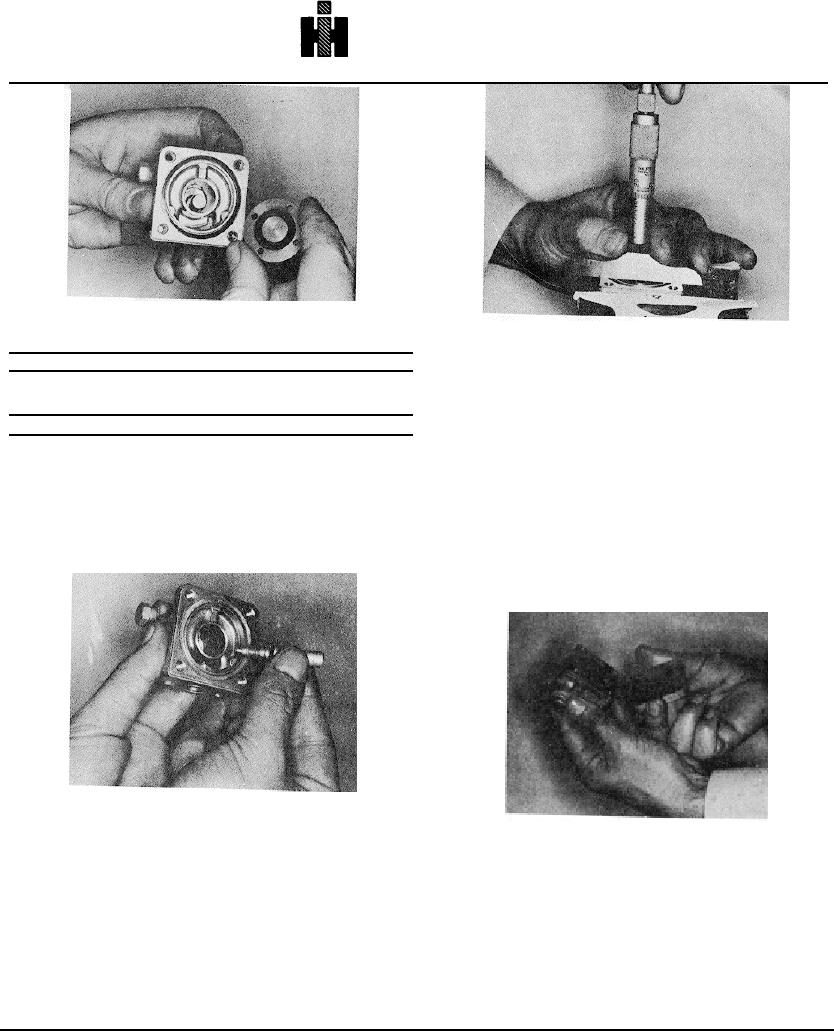

Fig. 5-38, F528. Inspecting plate type valve

Fig. 5-40, F530, Checking shaft tip depth

Table 5-6: Coil Resistances

Coil

4. Apply lubricant to housing "O" ring and seat in groove.

Coil

Voltage

5. Drop spring washer on valve with concave side up

Part No.

And Type

(Ohms)

and piloted around valve locator. Fig. 5-41.

7.5 0.5

134072

12 V.D.C. Single Terminal

6. Place fuel shield on valve housing and tighten screws

to 25 to 30 inch pound [2.8 to 3.4 N- ml torque.

Assembly

7. Energize valve and pump fluid through valve at 300

1. Install a new "O" ring on new override shaft and coat with

psi [2068 kPa]. De-energize valve and valve should

lubricant. Fig. 5-39.

withstand the 300 psi [2068 kPa] load with no leakage

2. Screw shaft into housing until it reaches bottom of its

through valve.

bore. Use depth micrometer set at 0.118 Inch [2.997 mm]

8. Should leakage exist, check the main body for nicks

and check distance from face of valve housing to tip

or depressions where body and plate come in contact.

Check the rubber seal in the plate for swelling or other

defects.

Fig. 5-39, F529. Installing override shaft

Fig. 5-41, F531. Assembling shut-down valve

of shaft. If necessary, screw shaft out until it is 0.118 inch

[2.997 mm] below housing face. Do not move shaft and

High Pressure Fuel Shut-Down Valve

press on knob until it contacts valve housing which will act

Some applications and/or approval tests require that

as a stop. Fig. 5-40.

rapid successive engine starts be made. Starts are

3. Place valve into valve housing with rubber side toward,

attempted as soon as the flywheel stops. Rapid starting

housing.

in this manner places an overload on the solenoid valve,

since it must open against pressure that has not

dissipated from the previous operating cycle. Fire engine

applications are an example of this requirement.

507