TRUCK SERVICE MANUAL

TRANSMISSION

Para 6-3

HT 700D SERIES TRANSMISSIONS

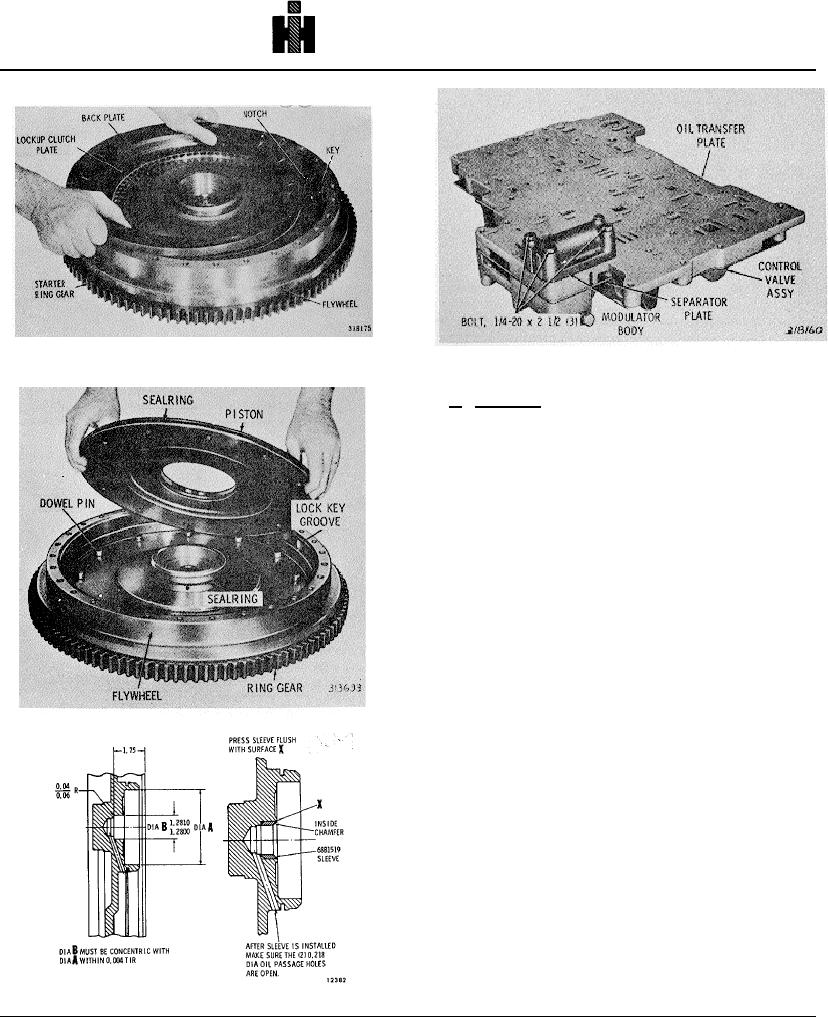

Fig. 6-5. Components of control valve assembly

Fig. 6.2. Removing (or installing) lockup clutch back

plate .

b. Assembly

(1) If the starter ring gear was removed, install a

new gear, as follows.

(2) Install the starter ring gear after heating it

uniformly to 4000F (2040C) maximum temperature. Be

sure the chamfers of the teeth are facing the proper

direction for starter pinion engagement. The ring gear

must seat firmly against the shoulder on the flywheel.

(3) Lay the flywheel on the assembly table, with

the cavity side upward, and install the sealring onto the

hub (fig. 6-3).

(4) Install a sealring on the outside diameter of the

lockup clutch piston and lubricate both sealrings.

(5) Place a pencil mark on the edge of the lockup

clutch piston opposite a dowel pin hole. Also place a

pencil mark in the flywheel bore, opposite a dowel pin.

Fig. 6.3. Installing lockup clutch piston.

(6) Install the lockup clutch piston into the

flywheel, alining the pencil marks, to engage the

recesses in the piston with the dowel pins (fig. 6-3). Be

certain the dowel pins are engaged.

(7) Install the lock key in the lock key groove of

the flywheel (fig. 6-2). Use oil soluble grease to retain it.

(8) Install the lockup clutch plate (fig. 6-2)

(9) Install the lockup clutch back plate, flat side

first, engaging the notch in the plate with the key in the

flywheel (fig. 6-2).

Fig. 6-4. Rework of flywheel-cross section view.

737