TRUCK SERVICE MANUAL

ENGINE

2. Use light finger pressure at the rocker lever contact

properly located.

surface to hold crosshead in contact with.valve stem

Compression Release Lever

nearest the push tube. Turn adjusting screw down until it

1. Install dowel in cylinder block if removed.

contacts its mating valve stem.

2. Position upper lever and bracket assembly to front

Note: With new crossheads and guides, advance

rocker arm housing and secure.

adjusting screw one-third of one hex to straighten stem in

3. Using screwdriver in slot in end of compression

its guide and to compensate for slack in threads. With

release shaft, turn shaft clockwise until lifting notch

worn crossheads and guides, it may be necessary to

contacts a valve push tube collar, move compression

advance the screw as much as 1/2 of hex in order to

release shaft lever to middle of travel; secure with

straighten the stem in its guide.

clamping screw.

3. Hold adjusting screw in position and torque locknut to

4. Secure spring on cylinder head with capscrew; hook

25 to 30 ft-lbs [3.5 to 4.1 kg m]; or, if ST-669 Torque

spring in lever on compression release shaft. Attach link

Wrench Adapter is used, tighten to 22 to 26 ft-lbs [3.0 to

to lower and upper lever; secure with' cotter pins.

3.6 kg m].

Fuel Pump/Compressor Drive/Accessory Drive

4. Check clearance between crosshead and valve spring

Bar 'engine to No. 1 cylinder, TDC position (firing

retainer with wire gauge. There must be a minimum of

stroke), continue rotating to 90 deg. ATC. In this

0.020 inch [0.51 mm] clearance.

position, the two center-punched marks on drive gear will

Rocker Lever Housing

mesh or index with two dash marks on camshaft gear.

1. Position new rocker lever housing gasket on cylinder

This timing. is required so external timing marks on

head.

accessory drive pulley will be properly aligned with timing

2. Loosen locknuts and back off rocker lever adjusting

mark on gear case to show valve and injector adjustment

screws two or three turns. Holding rocker levers in place,

positions, keyway of drive shaft will be at top. Secure

position housing on heads with ball ends of rocker levers

drive to cylinder block. Using a scrap gear case cover,

fitting into their respective push tube sockets. Install

fabricated as illustrated in Fig. 14-10, check accessory

lifting brackets and fan hub bracket support bell crank, if

drive gear backlash.

1. Attach a dial indicator gauge to the block with plunger

used.

3. Secure housing, brackets and support with

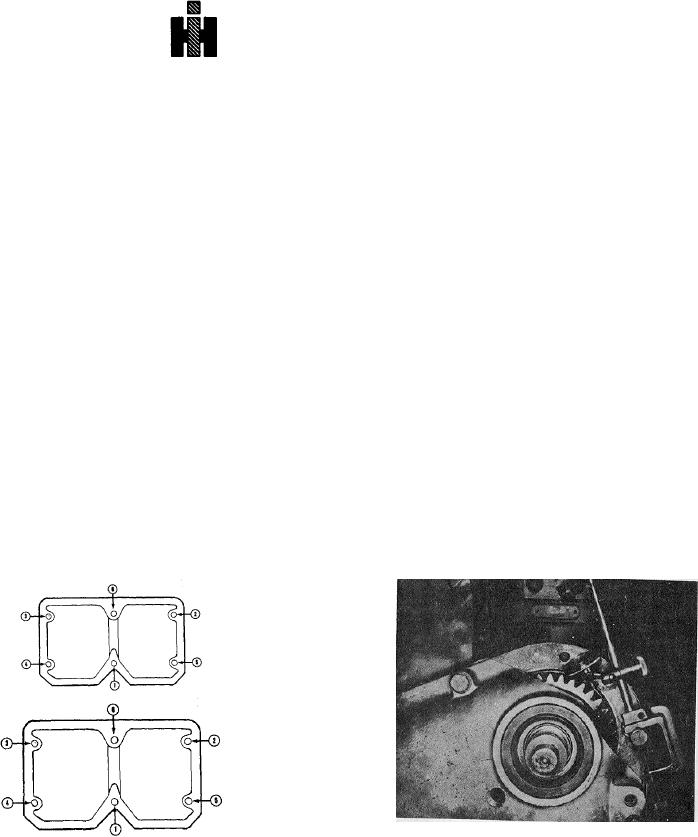

on accessory drive gear tooth. Fig. 14-10. Rotate gear

capscrews. Torque in sequence, Fig. 14-9, to 55 to 65

as far as it will move to take up backlash, zero indicator.

ft-lbs [7.6 to 8.9 kg mi.

Fig. 14-10, (N114132). Checking accessory drive gear

backlash

Fig. 14-9, (N11463). Rocker lever housing torquing

2. Rotate gear in opposite direction and read backlash

sequence

on dial gauge. Backlash should be 0.0045 to 0.0105 inch

Note: On 80 deg. tilt engines use ST-1182 Valve Spring

[0.114 to 0.267 mm].

Spray Nozzle Locator to check that oil spray nozzles are

398