TM 5-3805-254-34

6-38.

LOW PLANETARY CARRIER REPAIR (Con’t).

NOTE

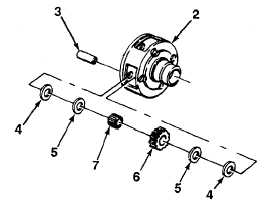

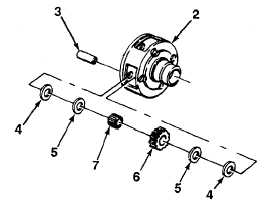

As each pinion pin is removed, keep pinion gear and four bearing washers together as a set.

4.

Press four pinion pins (3) from low planetary

carrier (2). Remove four pinion gears (6), eight

steel bearing washers (4), and eight bronze

bearing washers (5). Discard pinion pins.

5.

Remove roller bearing (7) from each of four

pinion gears (6).

b.

CLEANING AND INSPECTION

WARNING

Dry cleaning solvent, P-D-680, is toxic and flammable. Always wear protective goggles and gloves, and

use only in a well-ventilated area. Avoid contact with skin, eyes, and clothes, and DO NOT breathe

vapors. DO NOT use near open flame or excessive heat. The solvent's flash point is 100°F-138°F (38°C-

590C). If you become dizzy while using cleaning solvent, immediately get fresh air and medical help. If

solvent contacts eyes, Immediately wash your eyes and get medical aid.

1.

Clean metal parts with dry cleaning solvent.

NOTE

Pinion gears are a matched set. If any pinion gear needs replacing, all must be replaced.

2.

Inspect metal parts for cracks, breaks, wear, or other damage. Replace if damaged.

3.

Inspect four roller bearings and ball bearing for wear or damage (see TM 9-214). Replace if damaged.

C.

ASSEMBLY

1.

Apply thin coat of hydraulic fluid to surface of all metal parts.

2.

Install roller bearing (7) into each of four pinion gears (6).

NOTE

For easier assembly, pinion pins may be cooled and low planetary carrier may be heated.

3.

Position one pinion gear (6), two steel bearing washers (4), and two bronze bearing washers (5) into low planetary

carrier (2) and press in one new pinion pin (3). Install end of pinion pin 0.51-0.52 in. (12.95-13.21 mm) from front

surface of low planetary carrier.

TA703895

6-180